To ensure your safe operation, please strictly in accordance with the provisions of this manual.

This manual is copyrighted and may not be copied, cut, or modified without permission. Once found, the company will retain the contents of the manual without prior notice

Product Overview

Thank you for purchasing the 2nd generation brushless barrier gate. This product adopts the latest mold design technology, mold die-casting manufacturing technology, brushless control speed technology, and can be quickly interchanged, no clutch design, more reliable quality and more convenient use. The movement adopts two-stage worm gear transmission and curved crank three- link structure, the arm up and down are fast and stable. Easy maintenance and long service life.

Operation Time and Boom Length Configuration Parameter

Functions and Features

1 The running speed can be adjusted from 1.5s to 8s

2 Can be quickly interchanged

3 Open the barrier gate by motor wheel when power off ,automatically reset after power on

4 Curved crank arm three- link movement structure, the operation is stable

5 Wireless remote control control open/close

6 Auto reverse function(force adjustable)

7 Infrared photocells connector is available

8 Loop detector connector is available.

9 Well-integrated with car parking system equipment,with wire control(must be switch signal)

10 Connector for traffic light(AC220V,power less than 40W)

11 Offering dry contact signal for car parking system(COM,NC,NO)

12 Auto-delay when closing(adjustable)

13 RS485 or CAN network communication interface(no need to install module)

14 Counting interface

15 24V backup battery interface(Can be charged by using solar energy)

Technical Parameter List

1 Working temperature(motor): -30℃~+60℃

2 Rated voltage:DC24V

3 Running speed:1.5s-8s

4 Rated current:9.5A

5 Rated power:160W

6 No-load speed:1850rpm

7 Rated speed:1400rpm

8 Rated Torque:59.6N.m

9 Relative humidity:≥85%

10 Remote control distance:≤100M(in the open place)

11 IP Degree:IP54

12 Max length of arm:6M

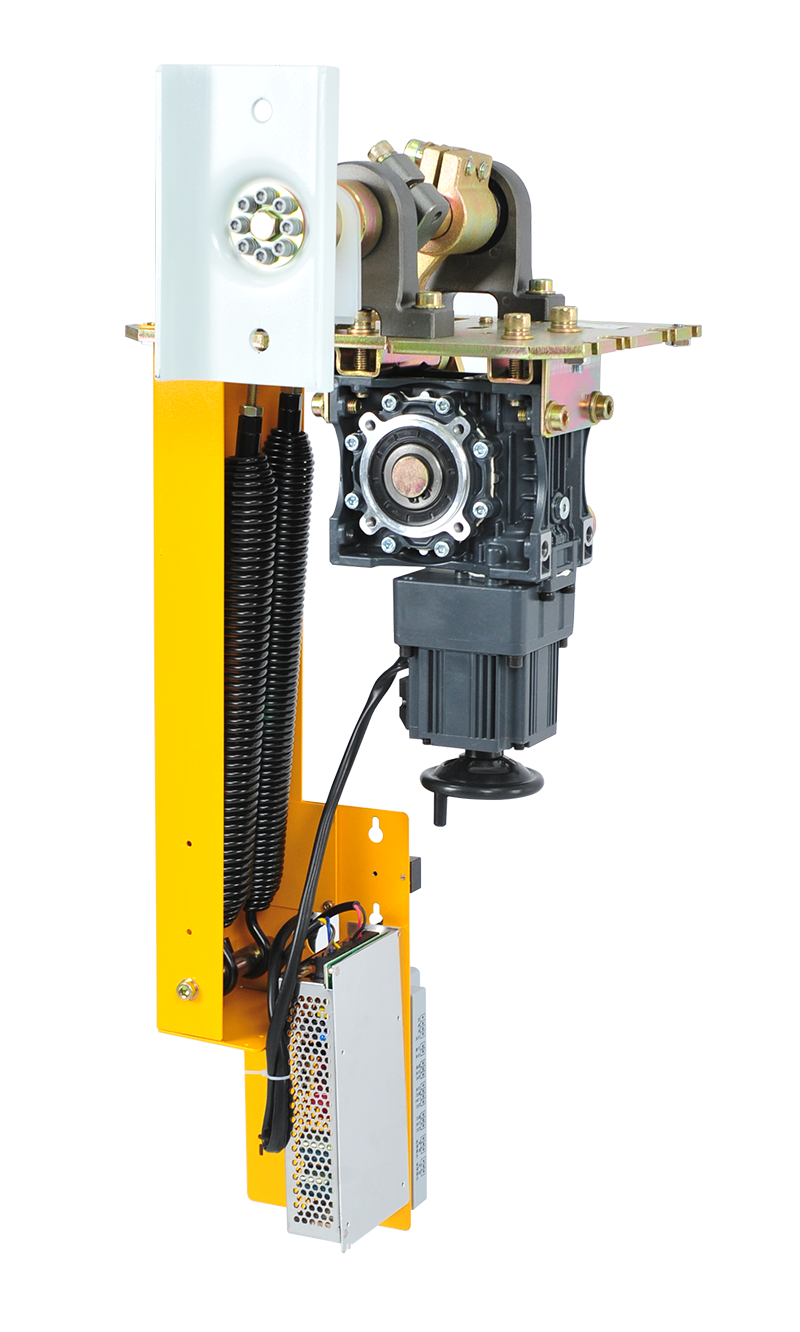

Machine core components

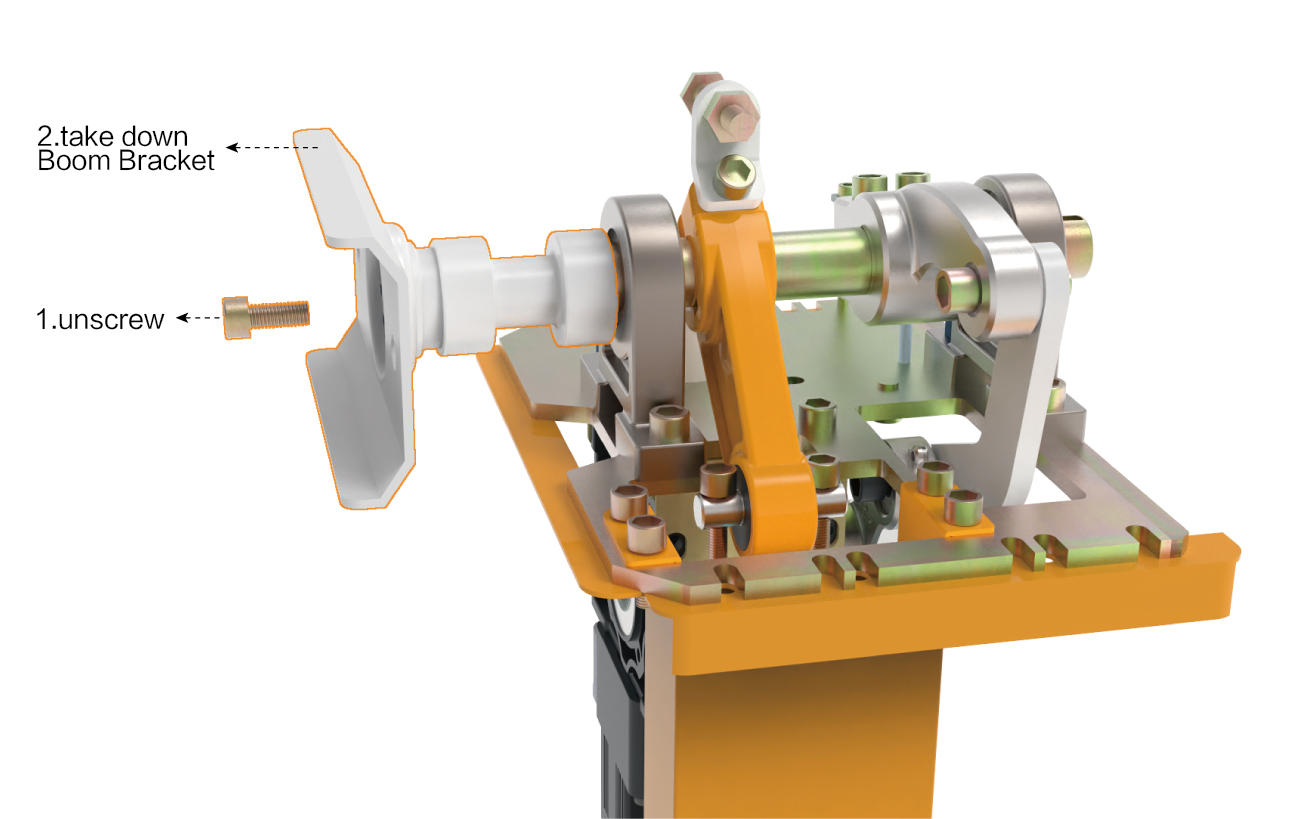

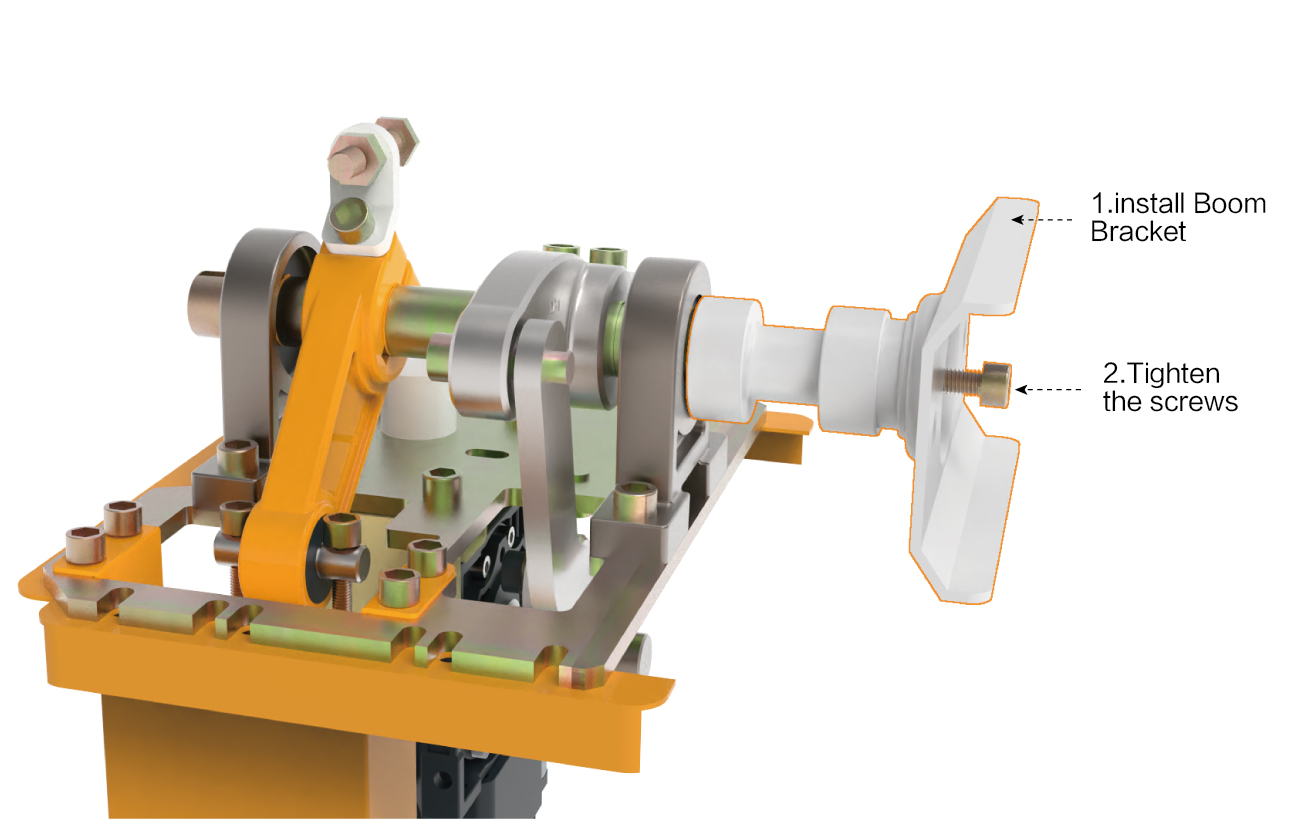

Interchange descriptions

The product direction can be interchanged, divided into 6 steps.

Step 1: remove the M8X20 inner hexagonal screw,take out the machine core;

Step 2: remove the electrical supporting plate from left side to the right side;

Step 3: remove the M1030 fixed screw on the boom tray (see figure 1);

Step 4: using the M14150 screw to pull out the boom tray head(see figure 2);

Step 5: install the boom tray head from the original left to the right side,or the original right to the lest side;

Step 6: put the machine core back into machine case, fixed the M8*20 hexagonal screw, direction interchange is completed, no need to adjust other Settings.

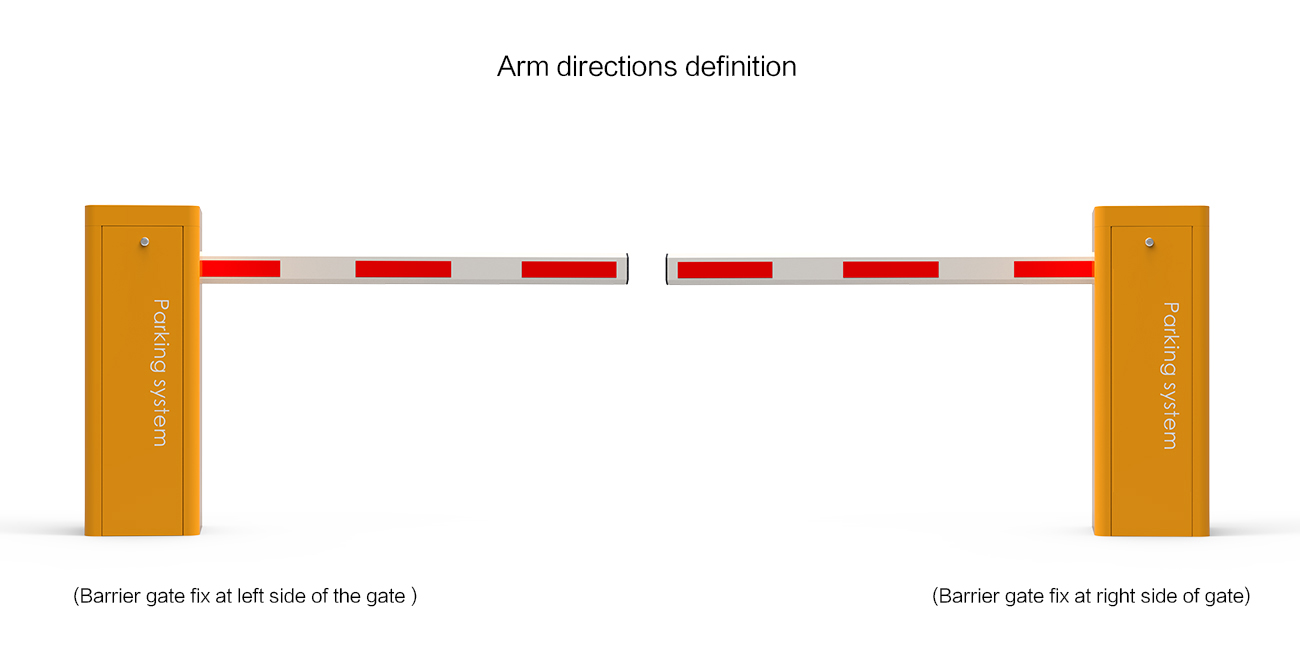

Installation direction definition

Installation, commissioning and use

1、Equipment installation

Please select the correct type of barrier gate according to the specifications of the pace,and then fix the barrier cabinet with expansion bolts(refer to Figure 3).

After determined the position,the barrier gate foundation should be done according to the site conditions,and also make the cast-in-place basement for the non-concrete ground.

2、Select and commission spring

The spring is stretchable one and the specification is as follows:

Diameter 4.5MM red color

Diameter 5.5MM blue color

Diameter 6.8MM yellow color

Diameter 7.0MM white color

The spring length is subject to the actual product. Design changes will be notified separately.

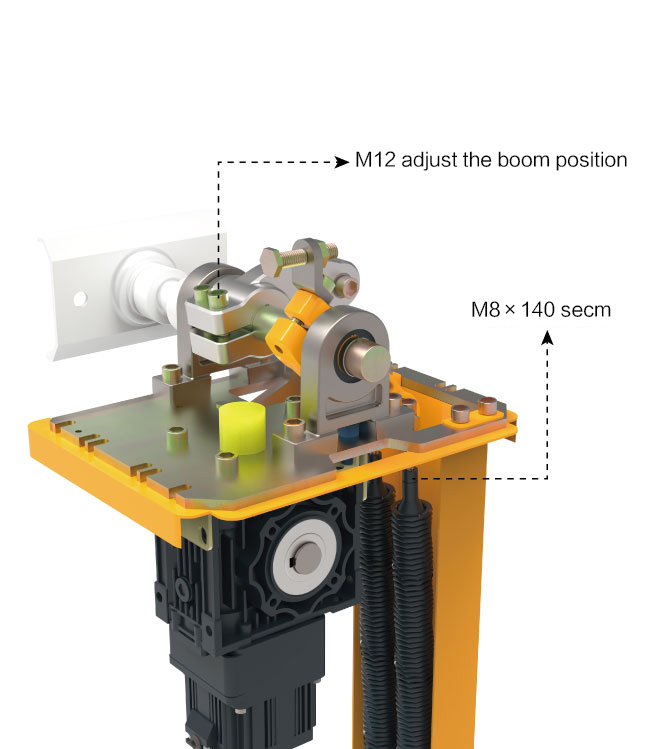

3、Adjust the Position of Barrier Arm

To adjust the position of the arm (for example, after exerting excessive force), please take the steps as below:

1.open the barrier gate door and remove the cover

2.loosen the two fasten screws of the DZ-1 on the boom shaft with the M12’s Allen wrench, so that the boom can be re-positioned by hand.

3.adjust the position of the boom (horizontal position, as shown in picture 1).

4.Use the hexagonal wrench to tighten the two fastening screws (72 Nm)

4、The parameter for selecting the balance tension spring

(the parameter is based on the company’s arm)

5、Installation,dismantlement and adjustment of spring

The steps as follows:

please keep the boom in the vertical(boom open)position.

7.2.5.1 Unscrew the M8*140MM screw with a hexagonal spanner

7.2.5.2 Unscrew the M10 screw in the hanging scroll,Pull the spring plank open and take off the spring

The installation steps are just the opposite of disassembly!

6、Boom position adjustment

1 First please set the arm horizontally and vertically through regulation nut to lengthen or shorten the connecting rod.And then tighten M12 safety nuts.

2 To make the arm well balance,please adjust the M8*140MM spring regulating screw accordingly.

3 For the barrier gate with double springs,please adjust the two springs simultaneously.

4 See the above picture when the arm is shaking during opening and closing. When the arm is shaking during opening, that means that the spring is too tight, you can try to loosen the spring repeatedly. When the arm is shaking during closing, that means that the spring is too loose. You can try to tighten the spring multiple times.

7、Electrical installation, wiring diagram

1 All the electrical connections are done before delivery and please do not change it randomly.The necessity is to connect the AC220V power and grounding connection.

2 Traffic light connector:it can connect power no more than 40W.

3 Infrared photocells an-hit connector: connect the switch signal for receiver output.

4 Loop detector connectors:it supports both externally and internally loop detector(only one way can be chosen).

If external type is selected,just connect the switch signal for loop detector output.

If the internal type is selected,need connect the wire signal to vehicle detector wire interface.

5 Car parking system connectors: connect the system switch signal to this connector,then it can control the barrier gate operation.

6 Limit switch signal of up/down:with output COM,NO,NC,it monitoring the status of the barrier gate.

7 RS485 connector:after chosen the options RS485 module,it can manage MAX 15 pieces of barrier gates by PC software.

8、Function setting description

When setting the function, please press the menu button on the control panel, the digital tube displays H00-00 or H00-other numbers, we correspond to the function parameter table code to enter the required function parameter setting, for example, H00-00 is the open speed adjustment, and then press the confirm key Enter the parameter setting, display the number on the digital tube, then press the up or down key to set the required starting speed digits, and then press the confirm key to complete the setting of the open speed.

Other function settings are just as usual.

9、Error code

10、Learning type remote control

The remote control using special IC learning code remote controller, 418MHz wireless frequency, strong anti-interference, long remote control distance, that can up to 100meters in good weather, use easily and durable. The receiver of learning code remote control can store 16 different remote control codes, and support unlimited number of same code remote control. The external receiver learned the remote control within 5 seconds when power on,press the open/close key at the same time to complete the learning, and reset to continue learn when not complete. If repeat the learning, open the external receiver shell, there is a white button on circuit board, hold down 15 seconds to delete the remote control code, continue to learn or press the white button to learn.

Arm length speed comparison table

Service Items

1 One year’s free servicing is supplied(not including the arm);

2 Lifetime charged servicing is offered;

3 Technology servicing is supplied.

The following situations are charged for servicing(or changing):

1 Broken by the wrong installation.

2 Broken by improper voltage.

3 The surfaces of the system destroyed by wrong installation or use.

4 Broken by natural disaster.

5 Overdue.

6 Servicing items out of our promises.

Product Maintenance

1 Keep the barrier gate clean

2 Check the joints ever month in case of any loose parts.

3 Check the spring elasticity after the barrier gate running 3000 times.

4 Check the easily worn-out parts(like the spring,limit switch),every half year and renew it.

5 Remote control distance will be shortened or not work in case like big object screening,battery exhausting,extreme weathers.